I had previously built a CNC machine years ago based on a design by "Joe" at CNCZone.com and the only issue I had was it was in my detached garage workshop and there was no easy way to transfer the gcode files from my home pc to the CNC machine other than USB stick. This was back when LCD monitors were not common yet and way too expensive so it had to have a tubed monitor attached. It ran Windows XP with Mach3 software on a AMD Pentium class pc. In 2004 era, laptops couldn't provide enough real time stepping power to keep up with the controllers so that wasn't an option and they also were not cheap!

I always wanted a touch screen controller that could easily move around the shop without worrying about a computer workstation and tons of cables having to drag around with it.

Fast forward 9 years and now I am in the process of building a 3d printer which as you know uses the same controls as a CNC machine and software has come a long way as well. The only issue with the majority of 3d printers today is they have to still rely on a laptop/pc connected to control it unless you use one of those LCD character displays and encoder wheel to select files from a SD card to print files from.

I came across a blog post a few months ago that mentioned using a Beaglebone Black with LinuxCNC running on it to control a 3d printer. This was the handy work of Charles Steinkueler and friends who did a wonderful job porting the LinuxCNC stepper engine over to the Beaglebone Black's ARM chip. You can download this image "MachineKit" from his site here.

The Beaglebone Black comes with a HDMI output on it to allow connecting direct to a LCD monitor and also supports touch-screens as well. This board is only $45 from Texas Instruments and is an awesome piece of hardware for this application! Besides the BBB running the software you still needed a "cape" to connect the printer to which was developed by Bas Laarhoven called BeBoPr. This has everything on board needed to control 3 steppers for the axis's and up to 2 extruders. Between these two boards I have everything needed to control the printer WITHOUT the use of a dedicated PC....perfect!

Now, on to the printer...

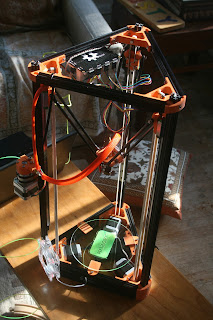

I saw a delta style printer in action on YouTube and was so memorized by the way it moved around and printed an object that I became hooked... The engineering, design and kinematics were ingenious and fun to watch. My mind was instantly made up and all I needed now was some plans, bill of materials and part sources to get started!

|

| Johann Rocholl's Kossel Legacy |

Stay tuned...